0086-415-3512089

2020/8/29Turbocharger installation

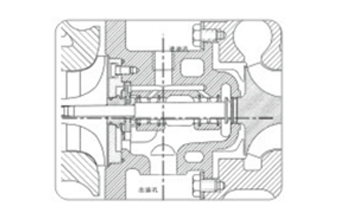

2020/8/29Turbocharger installationTo make the center line of turbocharger oil inlet and outlet as vertical as possible to ensure a smooth oil return.

2020/8/29Caution

2020/8/29Caution1.Due to the turbocharger is under high speed with high precision components,therefore,please do not disassemble unless necessary situation.

2.Please never use the actuator rod as handle.

2020/8/29Turbocharger false oil leakage

2020/8/29Turbocharger false oil leakageA.Mechanical seal mechanisam is normal B.Sealing function is normal,the internal pressure of bearing housing is not higer than the air pressure at both ends,oil can not flow to the high pressure chamber from the low pressure chamber.

2020/8/29Turbocharger damaged by abnormal objects

2020/8/29Turbocharger damaged by abnormal objects1.The surface of compressor wheel was damaged by abnormal objects A.Poor sealing of air intake pipe,air directly goes into the compressor without going through air filter. B.Do not replace the air filter regularly or use fake filters.

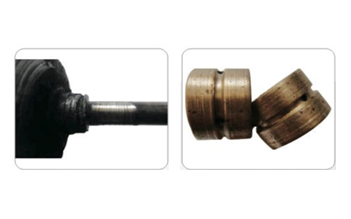

2020/8/29Turbocharger shaft loosen

2020/8/29Turbocharger shaft loosenJournal bearing,thrust bearing,main shaft and whole of bearing housing journal bearing abrasion caused by dirty oil,poor oil quality and used non-required grade oil.

2020/8/29Turbocharger abnormal sound

2020/8/29Turbocharger abnormal sound1. Air leakage noise A. Air leakage at engine exhaust manifold,turbine wheel and tail pipe,check according to exhaust trace B. Air leakage at engine intake manifold or compressor end,check by soapy water.

Fengcheng,Liaoning,P.R China